The Evolution of 3D Printing Technology

The Early Days of 3D Printing

3D printing technology, also known as additive manufacturing, has come a long way since its inception in the 1980s. The first 3D printing technology, stereolithography (SLA), was invented by Charles Hull in 1984. Hull's invention worked by using a laser to cure liquid photopolymer layer by layer, building up a three-dimensional object.

In the early days, 3D printing was primarily used for rapid prototyping in industrial settings. The machines were large, expensive, and limited in capabilities, making them accessible only to large corporations and research institutions. The materials available were also limited, with most early printers working with simple plastics or resins.

The Rise of Consumer 3D Printing

The real revolution in 3D printing began in the mid-2000s with the RepRap project, an initiative aimed at creating a self-replicating 3D printer. This open-source project significantly reduced the cost of 3D printing technology, making it accessible to hobbyists, small businesses, and educational institutions.

By the early 2010s, consumer-grade 3D printers became available for under $1,000, sparking a new wave of innovation and creativity. This democratization of technology allowed individuals to experiment with 3D printing in ways that were previously impossible, from creating custom household items to personalized gadget accessories.

Advanced Materials and Techniques

As 3D printing technology matured, so did the range of available materials and printing techniques. Today, 3D printers can work with a vast array of materials, including:

- Various types of plastics (PLA, ABS, PETG, TPU)

- Nylon and other flexible materials

- Resins with different properties (rigid, flexible, dental, etc.)

- Metal powders (aluminum, titanium, stainless steel)

- Ceramic and glass

- Biodegradable and sustainable materials

Modern 3D printing techniques have also evolved beyond the original SLA method to include:

- Fused Deposition Modeling (FDM) - extruding thermoplastic material

- Selective Laser Sintering (SLS) - using lasers to fuse powder materials

- Digital Light Processing (DLP) - using light to cure liquid resin

- PolyJet - jetting photopolymer materials

- Binder Jetting - depositing a binding agent onto powder material

3D Printing in the Gadget Accessory Industry

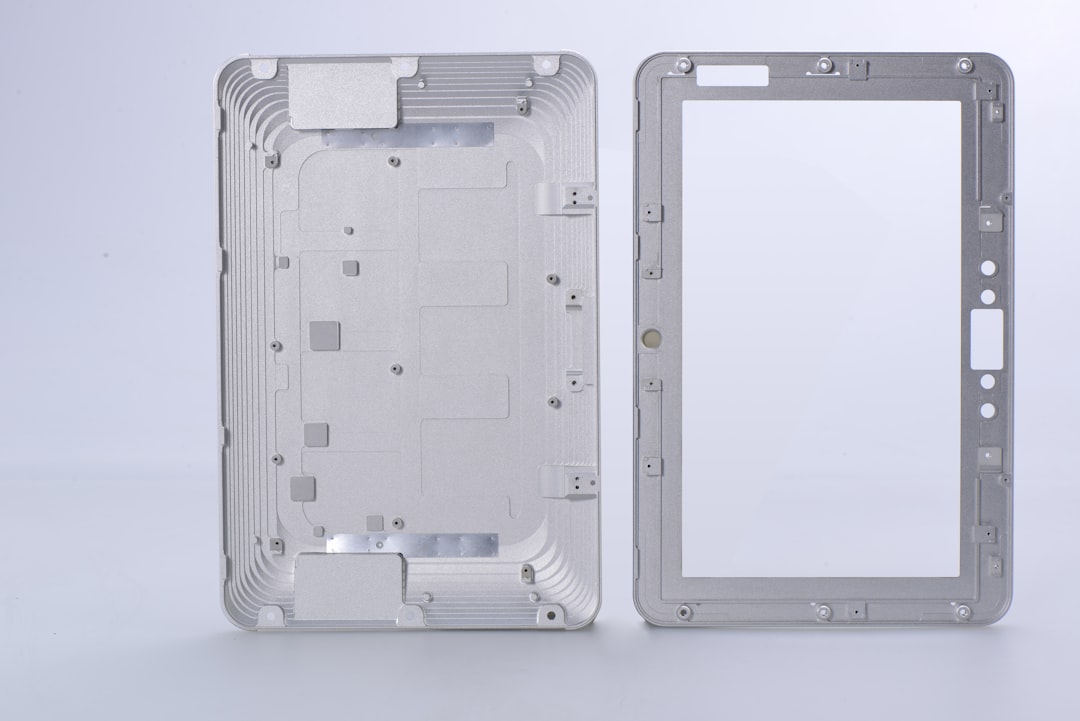

One of the most exciting applications of 3D printing technology is in the creation of custom gadget accessories. The ability to design and produce custom phone cases, laptop skins, and other device accessories has revolutionized how we personalize our technology.

At Farnmsklns, we leverage the latest advancements in 3D printing technology to create unique, high-quality gadget skins and cases. Our printers offer exceptional precision, allowing us to create intricate designs with fine details. The materials we use are specifically chosen for their durability, flexibility, and aesthetic appeal, ensuring that your custom accessories not only look great but also provide reliable protection for your devices.

The Future of 3D Printing

The future of 3D printing looks incredibly promising, with ongoing advancements in speed, precision, and material capabilities. Some exciting developments on the horizon include:

- Multi-material printing, allowing for complex objects with varying properties

- Integration with smart materials that can change shape or color

- Faster printing speeds for mass production capabilities

- More sustainable and eco-friendly materials

- Increased precision for even finer details

As 3D printing technology continues to evolve, we can expect even more innovative applications in the gadget accessory industry. From custom cases with integrated smart features to perfectly tailored accessories that blur the line between technology and fashion, the possibilities are endless.

Conclusion

The evolution of 3D printing has transformed it from an industrial prototyping tool to a versatile technology with applications across numerous industries, including custom gadget accessories. At Farnmsklns, we're proud to be part of this technological revolution, using the latest 3D printing advancements to create unique, personalized experiences for our customers.

Whether you're looking for a one-of-a-kind phone case that showcases your personality or a custom laptop skin that makes your device stand out, 3D printing technology makes it possible to bring your ideas to life with unprecedented detail and quality.